🧫 Cheaper and faster stem cell production

A new 3D-printed prototype for the extraction of stem cells offers potential for large-scale production with high quality - at a lower cost.

Share this story!

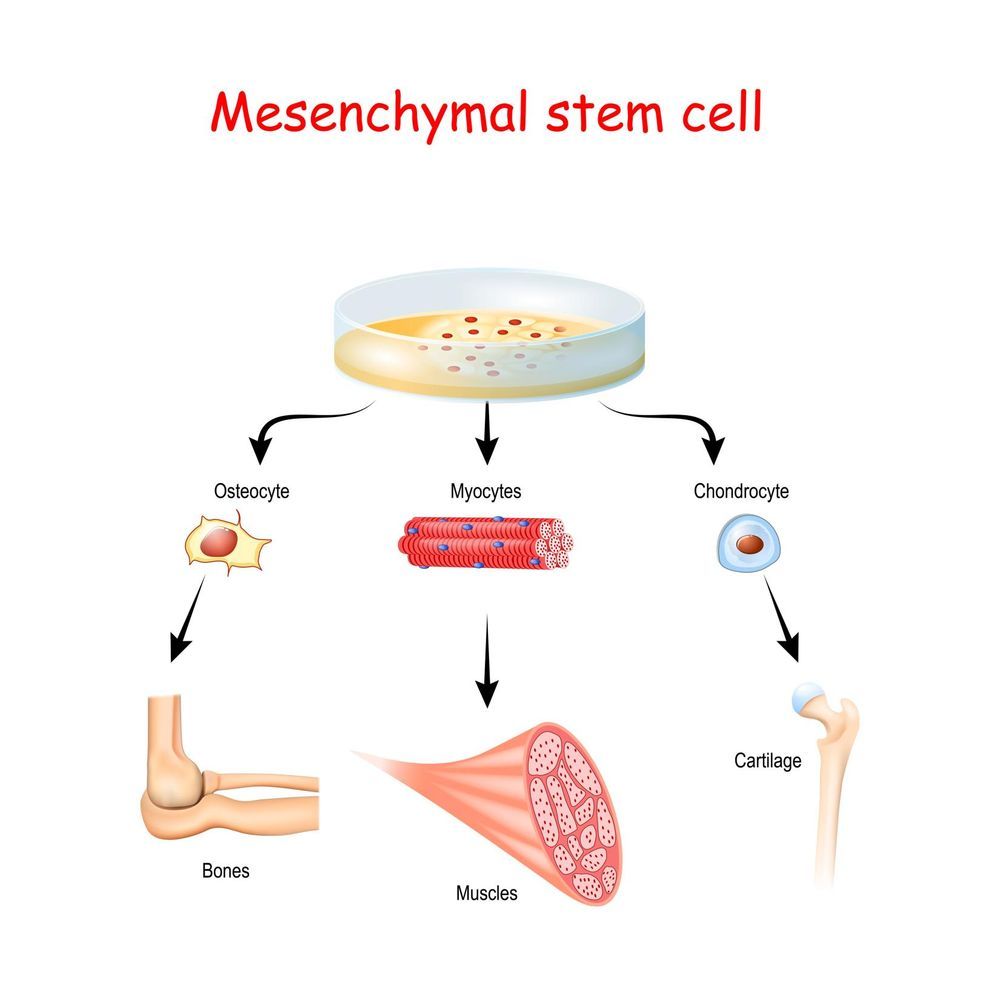

Stem cells are promising when it comes to treating a large number of injuries and diseases, as they can develop into a variety of specialized cells. So far, however, stem cell production has been expensive, time-consuming, and labor-intensive; but a new method may make stem cell therapy more accessible in healthcare.

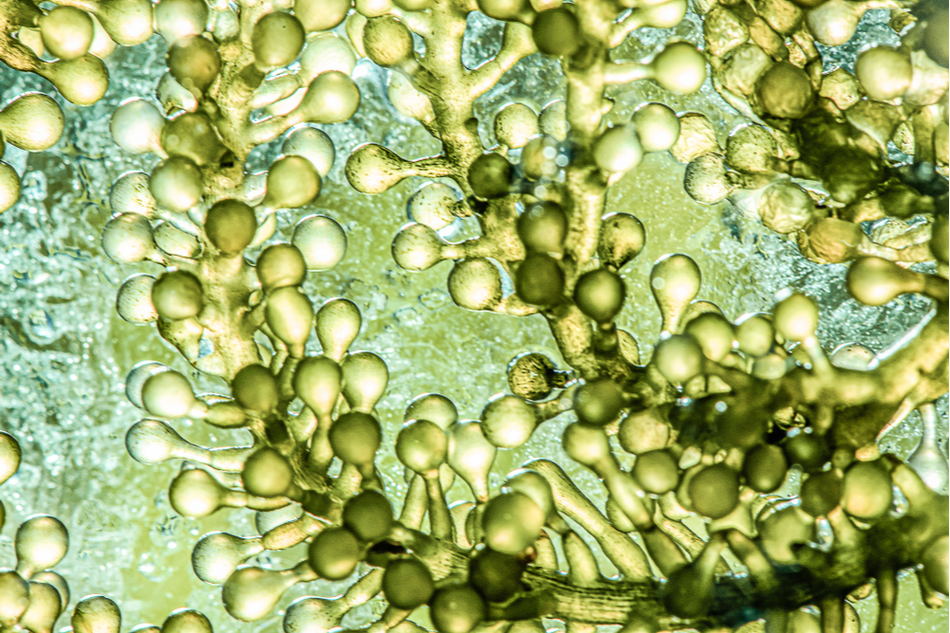

The University of Technology Sydney writes on their website about how they, together with an Australian biotechnology company, Regeneus, have developed a new method for producing stem cells. The research was led by Majid Warkiani and uses 3D writing and microfluidics to extract stem cells from bioreactors. The new method integrates several production steps into one single machine, which reduces the cost and time required to extract the stem cells.

"Our innovative technology, which uses 3D printers and microfluidics to integrate a number of production steps into one machine, can help make stem cell therapy more accessible to patients at a lower cost", says Warkiani.

Microfluidics is the term for the control of liquids at the microscopic level and can be used to manipulate cells and particles. Developments in 3D writing have made it possible to design tools for microfluidics, and thus in a short time develop new prototypes and build integrated systems.

The system was developed to process mesenchymal stem cells - stem cells from the bone marrow - a type of stem cell that can be developed into, among other things, muscle cells, bone cells, and cartilage.

Although the technology is still in the prototype stage, Warkiani announces that they are working closely with biotechnology companies to make the technology commercially viable. He also says that an important part of the new technology is that it is an integrated system, without any human intervention - conditions that are now necessary for good manufacturing methods.

In conclusion, he also says that the same technology and workflow can be used to meet other challenges that exist when it comes to industrial bioprocessing. Thus, quality can be increased and cost reduced for a range of life-saving products.

The entire study can be read here.

By becoming a premium supporter, you help in the creation and sharing of fact-based optimistic news all over the world.